Does this Dutch invention put an end to refrigerant in heat pumps?

14-02-2024

Installation

February 13, 2024 | 4 minutes read time

INSTALLATION MATERIAL W

WRITTEN BY: SANDER VAN DER MEIJS

A heat exchanger instead of a compressor in a heat pump. First of all, you no longer need toxic or environmentally unfriendly F-gases. In addition, it puts an end to the cycles of compression and degassing, which means you get a continuous flow of heat that is not constantly interrupted. ThermoSwap has found the solution for this, says Joost Minnaar, who explains their system at the VSK.

Current heat pumps lose a lot of efficiency due to the cycles of the refrigerant. It must first be pressurized and then degassed. Due to the latter, the heating process comes to a halt, which is why you need a buffer tank again. The efficiency due to these cycles is about 60 percent. "The efficiency of our solution is 98 percent," says Joost proudly. "We have a 0 footprint, which makes our system very good for the energy transition."

Continuous heat

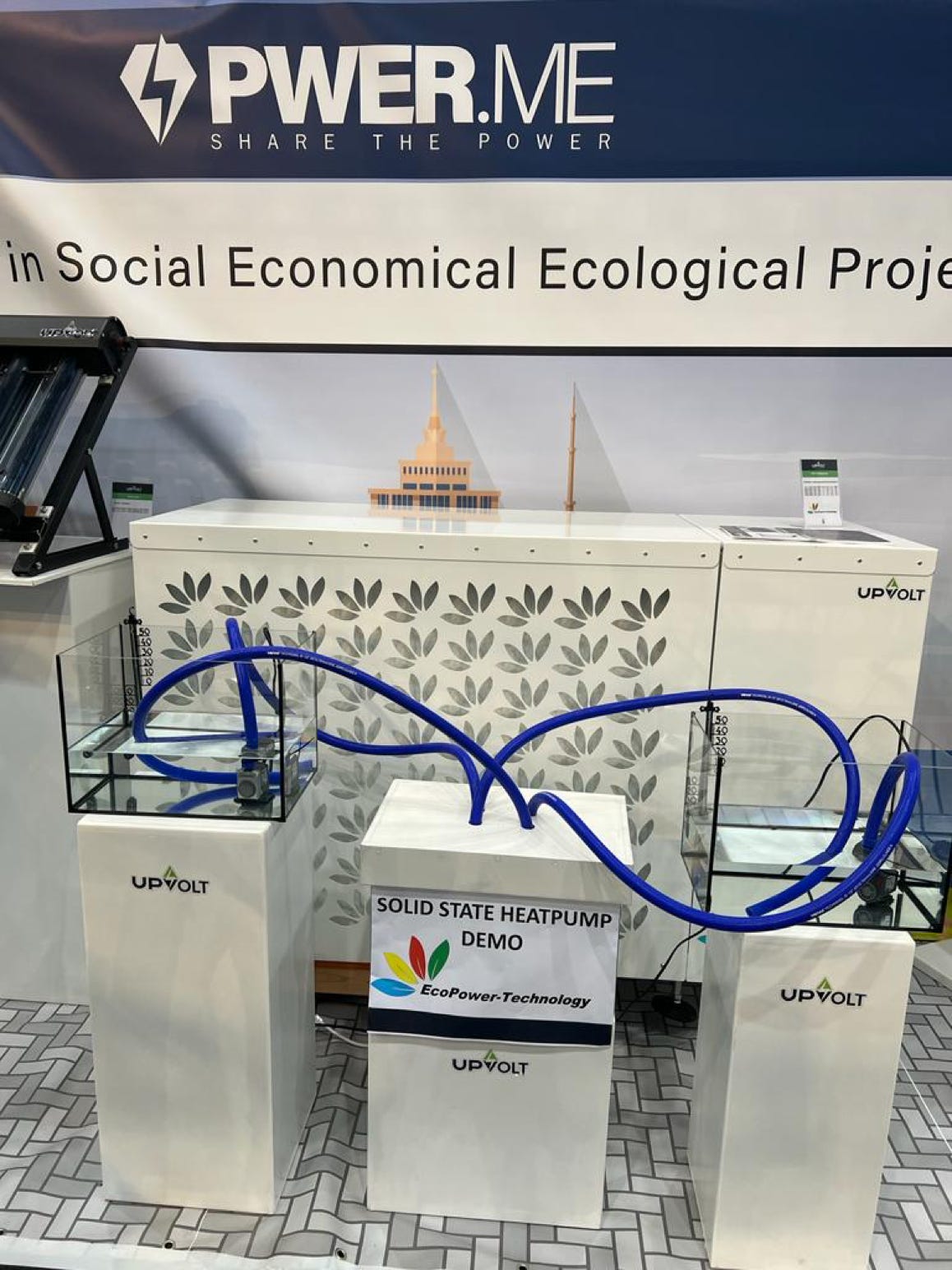

ThermoSwap uses heat exchangers. They have been working on the development for five years, but they only received the patent a week ago. So now they can come out of the garage and be present at the VSK. Joost demonstrates how it works in a test setup.

It is a modular system, so it can be easily scaled. If you want to bridge a larger temperature difference, you can mount more elements in series. Each element heats the water flowing through it by about one degree. Due to this small temperature difference, relatively little energy is required. If you put ten or twelve elements in series, you continuously heat the water by 10 degrees. If you need more capacity, you can place multiple of these series-mounted elements next to each other. "That is also much more compact than a traditional compressor," says Joost. "However, it does become heavier." To illustrate this, he lets someone feel a copper element. "But it can all run on solar cells, the system does not have a spike in energy consumption like a compressor does when the cycle starts."

Skepticism debunked

ThermoSwap's system is based on the Peltier effect. "This is why there are also quite a few skeptics," says Joost. "The Peltier element has a bad reputation because it is used in hotel refrigerators. Only lukewarm beer comes out of those things." But in those refrigerators, air is used as a conductor, he continues. "We use water and copper, which conduct much better."

Joost Minnaar is a chemist by training. Four years ago, he became involved in the development. "At first, I didn't believe in it myself," he says. "But I went there and saw with my own eyes that a 600-liter tank was heated to boiling point in 10 hours. I thought: this shouldn't be possible, I want to know everything about it."

In addition to eliminating the cycles, the heat exchanger has other advantages over the compressor. It has no moving parts, so it doesn't break. "The elements can easily last 30 years," says Joost. "So they can be reused over and over again. That is sustainable."

Water can also be heated to much higher temperatures than with a compressor. "With the plates of the heat exchanger, you could theoretically go up to 200 degrees, although you wouldn't want to. But you are no longer limited to low temperatures, as with current heat pumps. They usually only go up to 60 degrees."

Cooling and generating electricity from waste heat

The system will soon be tested by several manufacturers, a major installation company, and the UK Research Institute, which is the equivalent of TNO in the UK. "They have very large buildings and pools that they need to heat, but also lasers that they need to cool."

This also brings Joost to the steps that still need to be taken. "The next step is cooling. In itself, that shouldn't be a problem because you just have to reverse the flows. But there is still some engineering involved." Step 3 is then to use the Seebeck effect. This means that with this system, waste heat from, for example, power plants can be converted into electricity. "The cooling water is currently simply discharged into the sea, but with this, you can also extract electricity from it."

You can visit their booth at VSK, at the Start-up square, Hall 9, booth C017 on Friday.

Source: https://www.bouweninstallatiehub.nl/nieuws/dit-is-een-compressorkiller-in-warmtepompen